Texas Legend

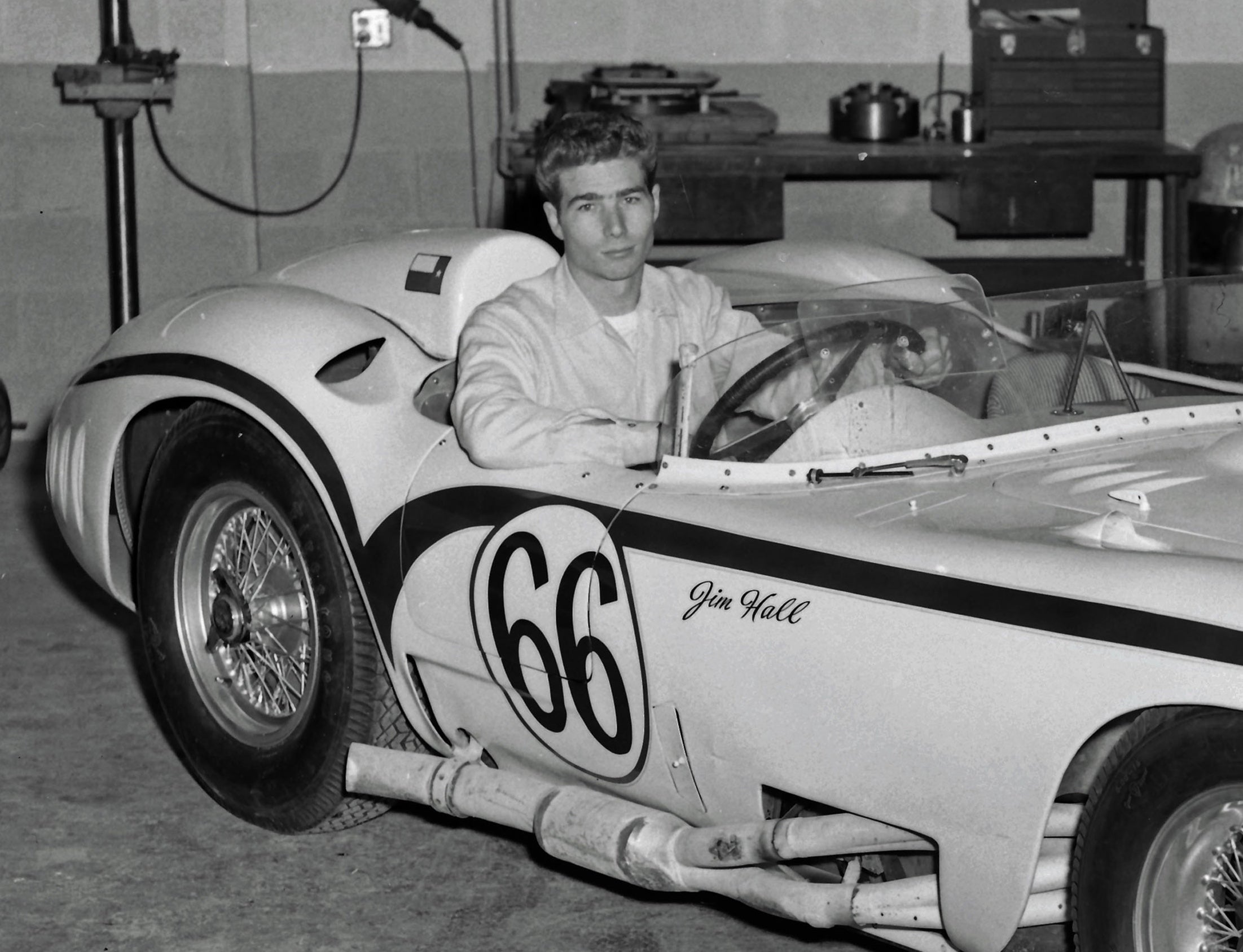

Jim Hall and his Chaparrals

- In stock, ready to ship

- Inventory on the way

Chapter 9

MIDLAND MASTERPIECE

One of the tricks of hindsight is that developments that were shocking at the time appear to later generations as simply part of the smooth, uninterrupted weave of history. Of course men walked on the moon. Of course we’ve mapped the human genome. Of course we walk around with handheld devices that put the entire store of human knowledge at our fingertips.

That’s the way hindsight works.

But back in 1962 no one foresaw exactly what kind of automotive revolution was about to take place over the next eight years and beyond at 6605 South Highway 349 in Midland, Texas or that Jim and Hap and their small, tight-knit crew would be the ones to make it happen.

In fact, to many reasonable observers, there were more reasons to doubt than to expect. Jim and Hap had little experience in car-building. They hadn’t forged “favorite son” relationships with leading racecar manufacturers the way Stirling Moss had with Lotus or John Surtees would with Lola, always first to get the latest models and upgrades. They weren’t even full-time racers. Both had successful businesses to run during the week.

The fact that they were Americans would have counted against rather than for them. At the time, all the great sports cars seemed to come from England, Italy or Germany. The fact that they were Texans would count even less. The few racecar-building centers there were in the U.S. were mainly in California and Indiana. There were sections of Los Angeles where you could find clusters of shops specializing in every aspect of racecar construction. Engines, brakes, chassis and bodywork. You just had to know who to ask.

None of that existed within a hundred miles of the Chaparral compound.

But to Hall and Sharp, most of these “disadvantages” didn’t matter or were advantages in disguise. No experience in car building? That just meant they had no investment in making incremental changes to the status quo. No favorite son relationships with leading racecar builders? The fact that they’d prepared, developed and competed in Coopers, Lotuses, Listers, Ferraris, Maseratis, Porsches, Elvas and Corvettes over the years meant they understood the art and science of racecar manufacture as well as anyone and were in awe of no one.

Building cars in the middle of nowhere?

Never tell a Texan he’s in the middle of nowhere.

So, they forged ahead. Firmly believing not only that there were better ways to solve every aspect of racecar design but that they could be the ones to do it, Texans to the core.

“We’d decided to build a mid-engine sports car with a Chevy, and we wanted to do it in the most modern way — efficient and light — that we could think of,” says Hall.

He ticks off the five main design criteria:

- Midship-mounted engine

- Low weight

- Lift-free, low-drag body

- Low cost

- Stiff chassis

The first was a given.

“I knew we needed a mid-engine car when we did the Chaparral 1,” says Hall. “But I was unaware of a suitable transaxle at that time. I thought the Troutman-Barnes approach to a front mid-engine car was kind of the next best thing.”

Jim Hall was beyond the point of having to settle for the “next best thing.”

The last criterion seemed obvious to Hall as well. They were going to go for as stiff a chassis as they could build.

“We had determined through our own experience and reading and talking to others that the Cooper cars weren’t as tunable as Lotus cars,” says Hall — the same Cooper, by the way, that had reinvented Formula 1 only a few years before. The root cause? Chassis stiffness. “We had read enough about it to realize that the ladder frame that Cooper used wasn’t very stiff in torsion, and that the Lotus cars with their triangulated tube frames were stiffer. [Lotus boss] Colin Chapman was fairly careful how he brought that through the cockpit area to make sure that it wasn’t too limber in the cockpit.”

Hall understood that with a stiff enough chassis you could do an even better job of optimizing vehicle performance for a given track. Choosing different springs, shock absorbers and suspension settings for a twisty, bumpy circuit than, say, a smoother one with a lot of high-speed turns. But only if the chassis were stiff enough for the changes to have an effect.

“You need to make it stiff enough in torsion,” Hall says, “so when you change the roll couple in the front, it has an effect on roll couple in the rear. If it wasn’t stiff enough, it wouldn’t matter what kind of suspension you put on it, because it was going to do whatever it did. It’s just too floppy to have any effect on the rest of the car.”

Or as Bob Marston, the longtime #2 man at Eric Broadley’s Lola Cars, would put it, Hall before others “recognized the importance of chassis stiffness as being the single most important factor of chassis design from the performance point of view.”

But how do you build a far stiffer chassis than others had managed to achieve? By looking beyond traditional car-building techniques.

“We thought about airplanes, the way they were designed and built with no frame basically” — monocoque construction — “and thought that was something we might use,” says Hall.

Remember here that both Jim and Hap were aviators before they were racers. Students not just of flying but of aircraft technology.

“I can remember my entire life Aviation Week and Space Technology came in the mail,” recalls Hap’s daughter Rosey. “We have a friend who was [later] a designer of the aerodynamics of the F-16, and they could sit and talk for hours and hours.”

Others had begun to venture down the same path. Semi-monocoque construction had appeared on the Le Mans-winning D-Type Jaguars of the mid-’50s. Chapman at this very moment, unbeknownst to Hall, was building his groundbreaking monocoque Lotus 25 Formula 1 racer. But Hall would be the first to do so in an open-cockpit mid-engine sports car.

The question of the hour was how stiff they were going to make it. The Texans chose 3,000 foot-pounds per degree as their target — a quantum leap forward — after measuring the torsional stiffness of the cars they’d been racing. They found that those racecars came in around 750 foot-pounds per degree. In other words, if you applied 750 foot-pounds of twisting force, they would twist one degree around the longitudinal axis between the planes of the front and rear suspension vertical loading points. Four times that value sounded like the kind of step-change they were after. If the new Chaparral could be as stiff as they hoped, that alone could help turn it into a force to be reckoned with.

To harvest the very latest thinking in structures they visited leading aerospace companies. It didn’t hurt that Hap’s uncle had been Secretary of the Air Force a few years earlier. The first defense contractor they saw was North American Aviation, near Los Angeles, in the summer of 1961. North American had designed the P-51 and F-86 Sabre fighter planes, plus a series of missiles. The Texans also visited Hexcel in the San Francisco Bay area, a leader in the then-new field of composites. They were impressed, but someone there told them they’d traveled farther from home than they needed to: “The company with the greatest composite technology in the world is right there in your backyard. You need to be looking in Fort Worth, Texas.” He was referring to General Dynamics’ Convair division, makers of the B-58 “Hustler,” the world’s first supersonic bomber.

At Convair Hall and Sharp met a young structures analyst named Andy Green. Green was responsible for the B-58’s composite wheelwell fairings.

The then-30-year-old Green had grown up in New Mexico and earned a master’s degree in structures engineering from Southern Methodist University in Dallas, not far from Carroll Shelby Sport Cars. He’d joined General Dynamics in 1955 where he’d been assigned to composites mostly because more senior structures engineers preferred more prestigious materials like titanium, stainless steel and high-strength aluminum alloys. They dismissed composites as “paint and bed sheets,” Green laughs. A sailing enthusiast, Green’s ambition was to start his own company building fiberglass boats, which at the time were barely a decade old. Fiberglass was an early form of composite.

“We got to talking to him about the composite they were putting on this supersonic airplane,” Hall remembers. “We thought, wow, that’s impressive, they’re going to use boat material to do this. So, he talked to us about the composite they were going to use [on the B-58], and how they were going to form it.

“He gave the reasons why you would use a composite. It’s light and stiff, and easy to shape. It’s easy to repair and has very high fatigue life. It’s low production, you’re not going to build very many parts, so you don’t want to spend too much money on the tooling.”

Containing costs was important to Hall and Sharp. Although both had achieved a modicum of financial security, they knew how quickly racing could drain bank accounts. They were well aware of people like Lance Reventlow — Raoul “Sonny” Balcaen’s old boss — who stopped building racecars because there was simply too much money going out the door. And unlike most racecar builders, Jim and Hap weren’t planning to sell customer versions to defray costs.

“Andy was pretty sharp,” says Hall. “Hap went back down and talked to Andy about, well, did he really want to get away from Convair and build boats, and Andy said, yeah, he really did. Hap said, ‘We’ll help you finance it if you’ll start with a project of building some stuff for us.’”

That moment, in the fall of 1961, is when the first true Jim Hall Chaparral was born. But even Green wasn’t aware of that at the time. He recalls how careful his fellow Texans were in dispensing information — you only knew, he says, what they wanted you to know.

“Hap didn’t come tell me he wanted to do anything about a car,” says Green. “He said he was an oilfield drilling contractor and wanted to have some lightweight portable buildings. I told him how I would build this building for him. He said, ‘That sounds good. I’ll let you know.’”

The meeting ended. Time passed. Days turned into weeks. Not a word from Hall or Sharp. Then Hap called and said, “Okay, I want you to come over and have a look at this business opportunity. I’ll meet you at Meacham Field.” Meacham was the airport in Fort Worth. Green assumed they would discuss the buildings in a conference room at the terminal.

He remembers what happened next like it was yesterday.

I went to meet him, and he said, “Are you ready to go?”

“Go where?”

He says, “We’re going to Midland.” I didn’t know about wealthy people. When he tells me he’s going to fly us to Midland, it blew my mind because not only did he own the airplane, he had a pilot that was flying the plane for him.

I’ll never forget what he did. He put a quarter in the wingtip of each wing, standing in the slot on a screw. We took off and we got a little bit up and the guy rolled the airplane, did a roll. We arrive in Midland.

The first thing he showed me was the quarters were still in the wing. Both of them, both sides.

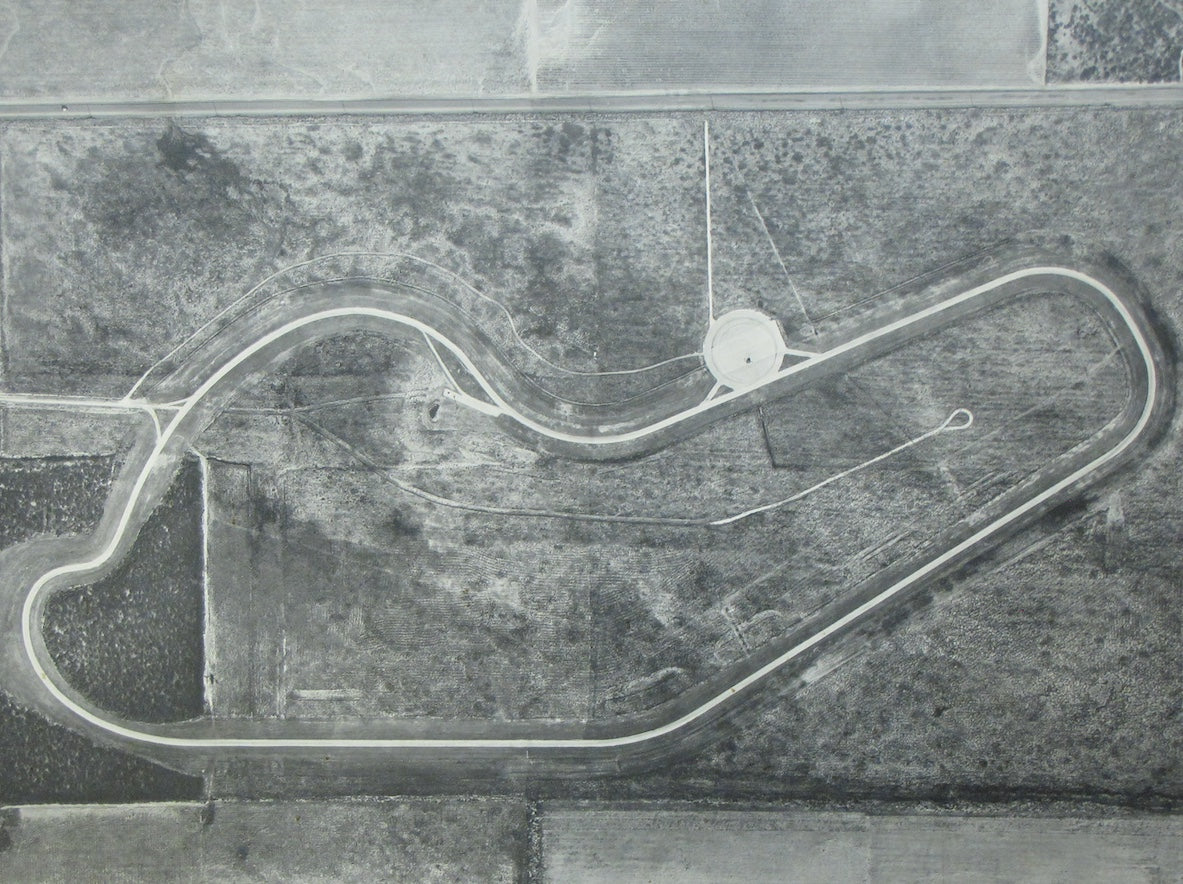

Once in Midland, they drove to the Chaparral compound at Rattlesnake, which at the time consisted of the track and two buildings Hall and Sharp had constructed on opposite sides of the parking lot to house their now-merging race shops. It was only then that Jim and Hap told him they wanted a chassis — for a racecar.

Green’s heart sank. He was there to discuss buildings. The opportunity to start his own company seemed to be vanishing before his eyes.

“I don’t know anything about a chassis,” Green blurted. “I wouldn’t have any idea where to start.”

Hall put his mind at ease.

“We’re not looking for an automotive engineer,” he said. “We don’t want anybody with any preconceived ideas.”

Green remembers Hall listing the other criteria for the new chassis, including greater fuel capacity and a layback seat — this last to maintain a low center of gravity for better handling. Then Hall and Sharp asked him how he would build it.

“I clutched up,” Green says, “because I came prepared to give a pitch on how I could build them the best portable building in the world. Here he’s asking me how I would do this car. There’s a blackboard. He says, ‘Make a sketch of how you’d do this.’

“I’m walking towards the board and I’m thinking about the Flying Dutchman,” a groundbreaking fiberglass version of the racing sailboat Green was designing in his spare time. A few years later he would sail it in the Olympics with media mogul Ted Turner. “I have the same problem as that,” Green continues. “The way I did it there was with torque boxes. I had four torque boxes; on the bow, the tanks on the side and a tank in the back.”

A torque box is an enclosed structure that’s stronger and more resistant to twisting than unboxed structures. Improvising, Green sketched two large torque boxes on the side of the chalk Chaparral chassis for fuel storage, a footbox at the front for the driver’s feet, another one underneath the driver’s legs for strength and one for the seatback.

A four-wheeled Flying Dutchman.

Hall studied the board. Inside his head, gears were turning. A composite chassis would satisfy three of his main design goals: greater stiffness, low cost and low weight. As it turned out, the entire tub would weigh just 120 pounds.

He looked at Green and said simply, “Well, that sounds okay.”

The deal was struck. The project moved forward. And with it in one fell swoop — albeit not yet fully evident to any of them — one of the most significant advances in racing history. How much so? Today, composite construction is used for almost every top-level racecar, including Formula 1, IndyCars, and Le Mans, not to mention many ultra-high-performance production cars. As Richard Falconer and Doug Nye put it in their book Chaparral, today “the only way to be competitive in world-class motor racing is with a composite chassis.”

Jim and Hap had found a better way, and the world would follow.

* * * * *

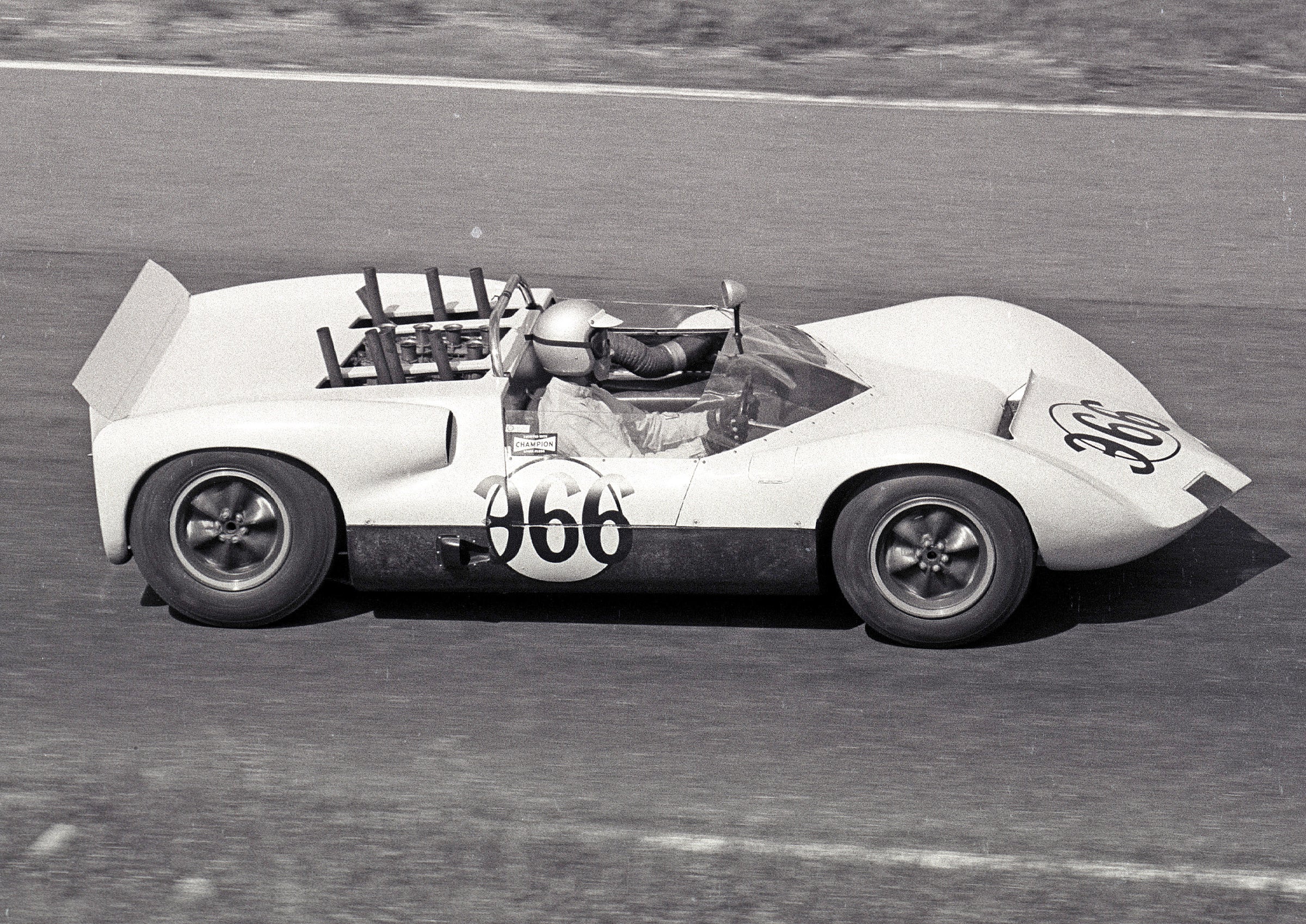

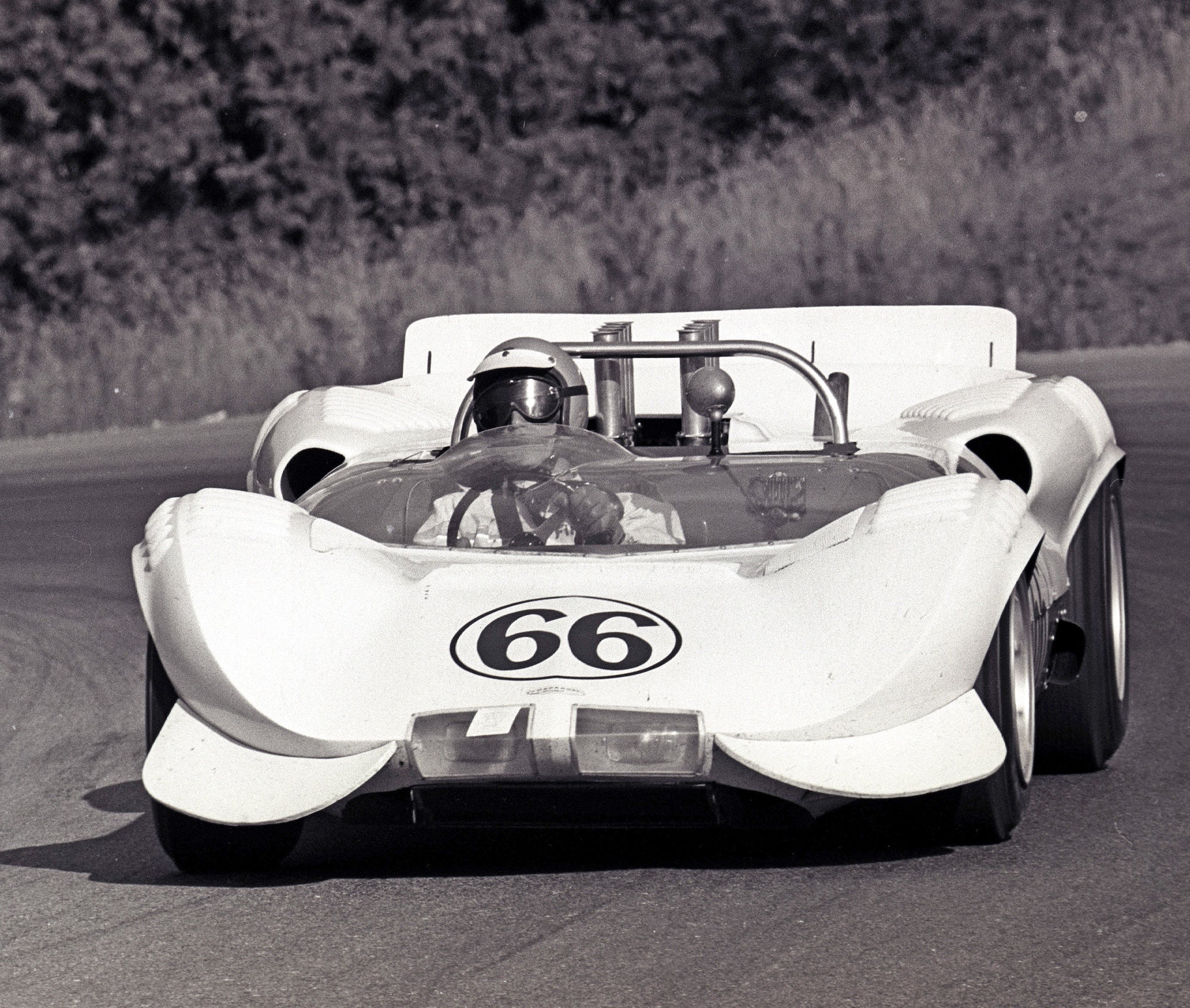

Another advance Hall sought for his new car was aerodynamic. He wanted a shape that was low in drag (for speed) with minimal lift (for safety and stability). Here, too, he sought the latest and best thinking, especially after the issues he’d had with the Troutman-Barnes Chaparral. (Although it was indeed the first Chaparral and today is designated Chaparral 1, Hall refers to it as the Troutman-Barnes car to distinguish it from the later Chaparrals that he designed.)

But where was that expertise?

The answer this time wasn’t aviation, for reasons beyond the fact that planes are designed to lift and racecars are designed not to. By the early ’60s most aerospace aerodynamics experts were focused on transonic and supersonic velocities, not the decidedly subsonic speeds of a racecar. The auto industry didn’t have much to offer either. With gas at 25 cents a gallon, few automakers bothered to subject new models to wind-tunnel testing and most racecar manufacturers couldn’t afford to.

But here’s the thing: even when people did put cars in wind tunnels, the results were often useless for reasons that wouldn’t become apparent for another decade.

Wind tunnels are just that. Tunnels with a large, wind-generating fan at one end blowing air past a given object. The tunnels act like the inverse of the real world: instead of the vehicle speeding through still air, the air flows past the stationary vehicle. Nevertheless, the results are remarkably predictive of real-world aircraft performance, so the inversion works.

Not so with cars, which are placed not in the center of the tunnel, suspended in midair, but on the floor, to represent the vehicle on a road. In those days, the car was stationary. The wheels were stationary. The road was stationary. And because car people believed air passing under a vehicle had negligible effect on its overall performance, they rarely bothered to finish the underside of a wind-tunnel model.

Turns out, there were several issues with that. It would be the mid-’70s before aerodynamic experts discovered that for automotive wind-tunnel results to be accurate, both the ground plane and the wheels needed to be moving too — like they would in the real world. Even for cars with full fenders, like the Chaparrals. Championship-winning designer Tony Southgate:

The moving floor was introduced in 1975. I was the first in the UK to develop a new design using it. The car was the [Formula 1] Shadow DN5, which when it first appeared was aerodynamically the best car on the grid. The greatest reason for this was that the center of pressure was completely different when measured with the [wind-tunnel] floor moving — 10 to 15% less on the front axle so I simply re-engineered the distribution by creating larger front-wing sections and downforce-generating nose shapes.

The comparison was very easy to check; you simply switched the floor off when running the tunnel to get the old figures.

In other words, designers saw greatly different results with the wind-tunnel floor or “ground plane” moving, results far more representative of real-world behavior. Southgate used this knowledge to achieve 750 pounds of downforce at 150 mph on the DN5, which he estimates was about 250 pounds more than the competition.

It was also critically important for the car, whether a partial- or full-scale model, to possess every external detail of its real-world counterpart, top, bottom or otherwise. In the ’60s, on the rare occasions when racecars were submitted for wind-tunnel testing, they were usually basic shapes, with no drivetrain or suspension, or functional scoops or intakes. Often the underside was completely hollow. This also led to results that differed dramatically from real-world behavior.

But recognition of these factors was still a decade or more away. All Hall knew was that he wanted to pick the brains of the best automotive aerodynamics experts he could find.

Who might they be?

The answer came unexpectedly at the 1962 June Sprints at Road America, one of the premier Midwestern sports car events. Over the course of the weekend, Hall and Sharp each won their class — Hall in his Chaparral 1, Sharp in his Cooper Monaco. At one point they walked through the paddock and came across a stunning, low-slung silver sports car unlike any they’d seen before: the Corvair Monza GT.

It was customary in those days for GM designers and engineers to attend the Road America races. Often, they brought concept cars with them to gauge public reaction to new ideas. The Monza GT, which did parade laps at one point, was a sensation. The crowd, mainly from Wisconsin, Illinois and surrounding states, swarmed it. Soon it would appear in car magazines across the world. Hobby shops would sell model kits of it by the tens of thousands.

For Jim, the Monza GT was as intriguing for what was under the skin as on it. The Monza featured a Corvair engine and transaxle but flipped to create a mid-engine configuration instead of the rear-engine layout of the production model. It had been styled by Larry Shinoda and Tony Lapine, two of GM’s finest stylists. Shinoda, a Japanese-American who’d been interned as a child at a U.S. WWII relocation camp, had worked on the Chevrolet Stingray racecar and the production, split-window ’63 Sting Ray coupe that would make its debut to universal acclaim a few months later. Motorsports Hall of Fame inductee Pete Brock, another former GM designer who worked on the original Stingray concept as well as the 1965 world champion Cobra Daytona Coupe, calls the Monza “the finest GM concept ever.”

There was good reason for Hall and Sharp to be intrigued with the car and there was almost instant rapport between them and the GM men accompanying it. These included Bill Mitchell, head of GM Styling and an avid racing fan, and Frank Winchell, head of the GM skunk works known as Chevrolet Research and Development — Chevy R&D for short. Jim Musser was Winchell’s #2 at the time.

“We were there with the car when Jim Hall and Hap Sharp came up,” Musser says. “They were interested in the car because Jim was in the process of building his mid-engine Chaparral. We got into a lengthy conversation about that.”

Musser remembers Hall inviting Winchell to come down and look at their facility in Midland, and Mitchell in turn invited Hall to come to the General Motors Technical Center in Warren, Michigan, which he did within weeks of the Road America event. At one point Hall asked his hosts about the latest thinking in aerodynamics.

The answer, they said, was, in effect, the Monza GT. Kent Kelly, 30, was working in a special advance-planning department within GM Styling devoted to conceiving cars 10, 20 years into the future. Although the Wisconsinite was trained as a chemical engineer, he was put in charge of aerodynamic studies. That’s how little was understood about the field at the time. One day Winchell said to him, “You know, Hall’s doing the Chaparral. You guys [at GM Styling] are starting to get into aero. Why don’t you make a stop when you’re going out of town next and talk to him.”

Kelly knew there was only so much they could offer.

“We had no wind tunnel,” Kelly recalls, “and we’d done almost no testing, so what we were doing was kind of out of the book and out of our head.”

Occasionally, Kelly would take scale models of new vehicle concepts to wind tunnels around the country, including Caltech. Less than a month earlier, on May 21, 1962, he had taken a 3/8th scale model of GM’s XP 775 — not the Monza GT, but almost identical in shape — to the Chance Vought Aerodynamics Division tunnel in Dallas.

Kelly shared the testing report with Hall.

* * * * *

It’s one thing to conceive a new kind of racecar. It’s another thing entirely to build it. Producing a car, especially in Midland, Texas, where there was little racing infrastructure, would require a remarkable crew. Between them Hap and Jim had assembled a small team, including Frank Lance, Donn Allen and body man Foy Barrett from the Carroll Shelby Sport Car days in Dallas. But they were focused on racing and maintaining the cars Jim and Hap were running during the 1961 and ’62 racing seasons. They needed additional people to build the new Chaparral basically from scratch. The first person they hired in the fall of 1961 was one of Chuck Hall’s friends from Colorado.

Gary Knutson, 24, was the son of a schoolteacher and a portrait photographer in Colorado Springs. A tall, rangy straight shooter with a penchant for practical jokes, Knutson had earned a degree in mechanical engineering from the University of Colorado. His passion for cars had helped turn him into an excellent mechanic as well. Like Chuck, Knutson was interested in road racing. When Chuck set up a small shop in Boulder to work on his cars, Gary joined on. At one point they took Chuck’s spidery 2-liter Osca and installed a small-block Chevy fitted with a McCullough supercharger, shades of Jim’s supercharged Lister-Chevy. When they started running Formula Juniors, Knutson homebuilt a dynamometer. A resourceful guy.

Knutson met Jim six years earlier when he and a buddy purchased a new Lotus 11 from him at Carroll Shelby Sport Cars, “but he didn’t know me from Adam,” Knutson says. Later, when Jim started racing at Nassau and Sebring, which required more on-site support than the local SCCA events, Chuck would send Knutson down to help. Jim saw immediately how capable he was.

“When I finished up school, I didn’t really know what I was going to do next,” remembers Knutson. “Chuck said, ‘Why don’t you go down and go to work for Jim?’” Chuck told him about the mid-engine car they were building. “I thought that sounded like good fun and a good job, so I packed up and moved to Midland.”

Jim and Gary found they worked well together. Jim, the idea man and the designer. He decided the layout of the car: engine location, the type of body and chassis, the placement of the major controls. Gary was the builder and problem-solver. Once Jim determined the suspension geometry, Knutson fabricated the components and the brackets to attach them to the fiberglass chassis using techniques learned from Green.

“Gary was an instrumental part of putting together Chaparral 2, the first car,” says Hall. “Gary had a lot of ability and was a smart guy. And just like the rest of us, Gary would work 24 hours if needed be. I’d say he had as much input to the actual putting together and finalizing of the design of the Chaparral 2 as anybody.”

* * * * *

Kelly remembers spending two days in Midland in the summer of 1962 sharing the wind-tunnel report for the XP 775 with Jim. In all, Kelly had done 65 wind-tunnel runs at Chance Vought, adjusting the nose profile to see if they could eliminate lift.

“They raised the nose on it, and while they were in there, [Kelly] told me that he believed that if they’d raised the nose a bit more it really would have worked,” says Hall. “It would have killed off the front-end lift of that car.

“So that’s what I did. I took pretty much that [XP 775] shape in plan view and raised the nose a little bit more,” says Hall. “That’s the way we built the first body. In fact, we built the body pretty much like that model that they ran which had that V-shaped windshield also.

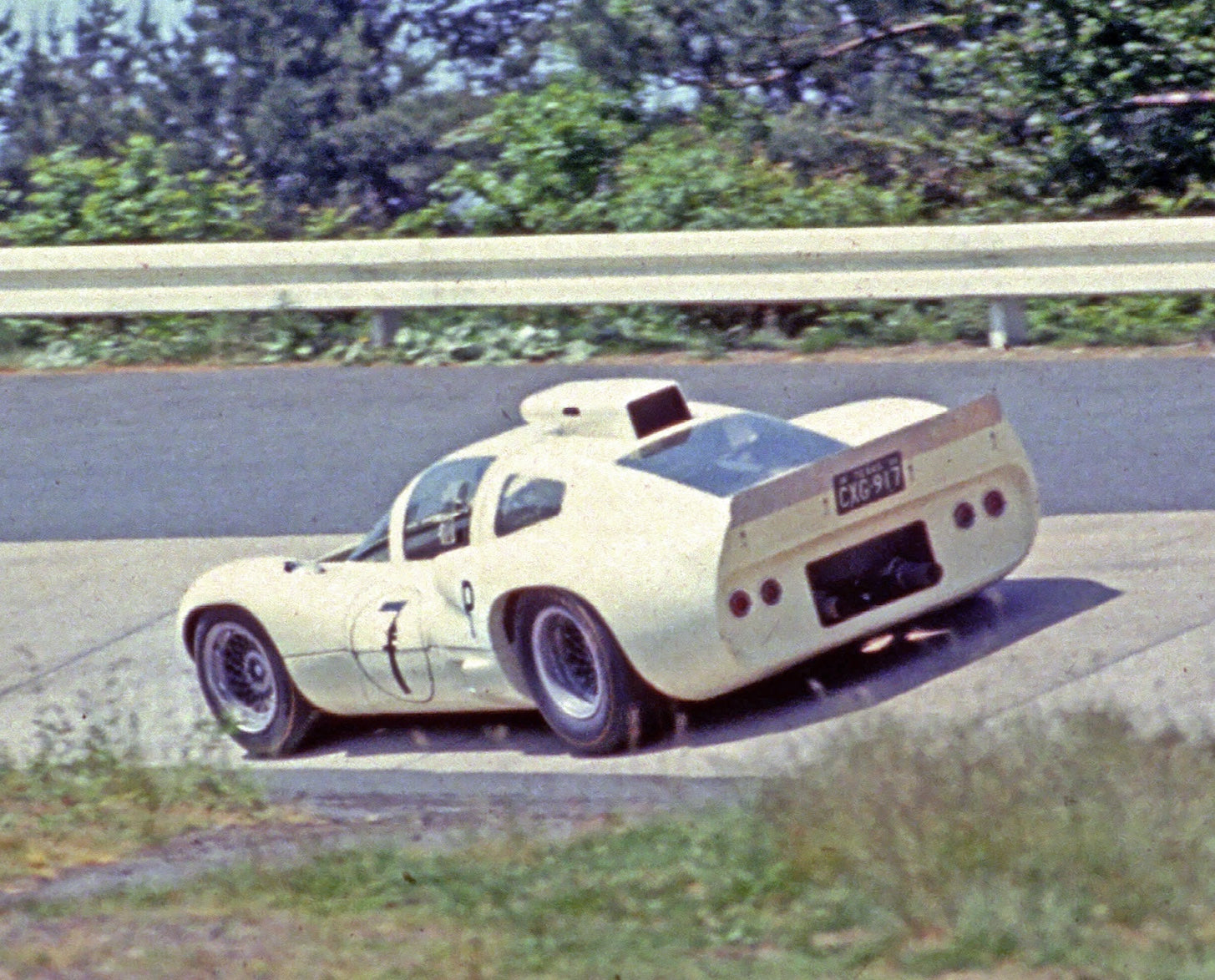

“We built it as a coupe thinking that someday we might want a coupe, and that we didn’t have to have the top on it, basically. We weren’t thinking about running a coupe. We just said, ‘Well, as long as we’re building the mold, why don’t we do that part too?’”

It was messy, painstaking work. The shop was a simple 540 square foot building. Concrete floor. Workbenches. Toolboxes. Drill presses. There was an air conditioner to stave off the 90-degree-plus summer heat.

“The Chaparral 2 body was built by putting all the components in place on a small plate to simulate the height of the chassis,” says Hall. “The engine, the transmission, the wheels were there. Driver’s seat, radiator. We put it all there. Then we made some plywood bulkheads to just cover the shape of what we had, then we started building the body on it.”

A major automaker would have used clay models and a team of highly trained sculptors. In Midland, Hall and his tiny crew had to improvise.

“We did it with Styrofoam,” Hall remembers. “We just put Styrofoam blocks on there and sawed it with a big-toothed saw to get to shape it more or less like we wanted it… then we finished it in body putty really. We put body putty all over it and filed it with Stanley tools and sanding blocks until we got it kind of in shape. Then we painted it and took a mold off of it. The body plug was made out of wood and Styrofoam and body putty basically.”

Everyone pitched in, including Sandy.

“We built this plywood and Styrofoam mockup,” Knutson adds, “which was a horrible job, because none of us knew anything about how you did that. I guess I should have learned how to do clay, in hindsight.”

What happened to the coupe body seen in these photos?

“Jim decided we ought to destroy that thing,” remembers Knutson. “Over about 50 yards from the shop, off to one side of the racetrack in a mesquite thicket, there was a dump — that was in the good old days — all the junk just went out there. So, the body buck ended up there.

“I ended up burning it. It made a spectacular fire.”

As 1962 was coming to an end, the Chaparral 2 was taking shape, led by a couple of guys few had reason to believe would build the world’s next great racecar, in a place everyone but themselves might have thought as the middle of nowhere, racecar-wise. The chassis and new roadster body were coming together in Midland. The engines were being built at Art Oehrli’s shop in LA, the Chevys chosen not just because they were American, but because of their low cost.

“We wanted to do these things in the most economical way we could and that’s one of the reasons for using Chevys,” says Hall. They would mate the Chevy to an Italian-made Colotti transaxle, one of the still-too-few gearboxes that could handle serious V8 torque. And Frank Lance, among his many other talents, was as good as they came when it came to making transaxles hum. He would later be hired away by Carroll Shelby’s Ford GT effort in part to solve their massive problems with — wait for it — Colotti transaxles in their battle against Ferrari for supremacy at Le Mans.

Everything seemed to be falling into place to make a full-scale assault on the 1963 American sports car racing season.

Key content

• First-ever book in which Hall tells his own story.

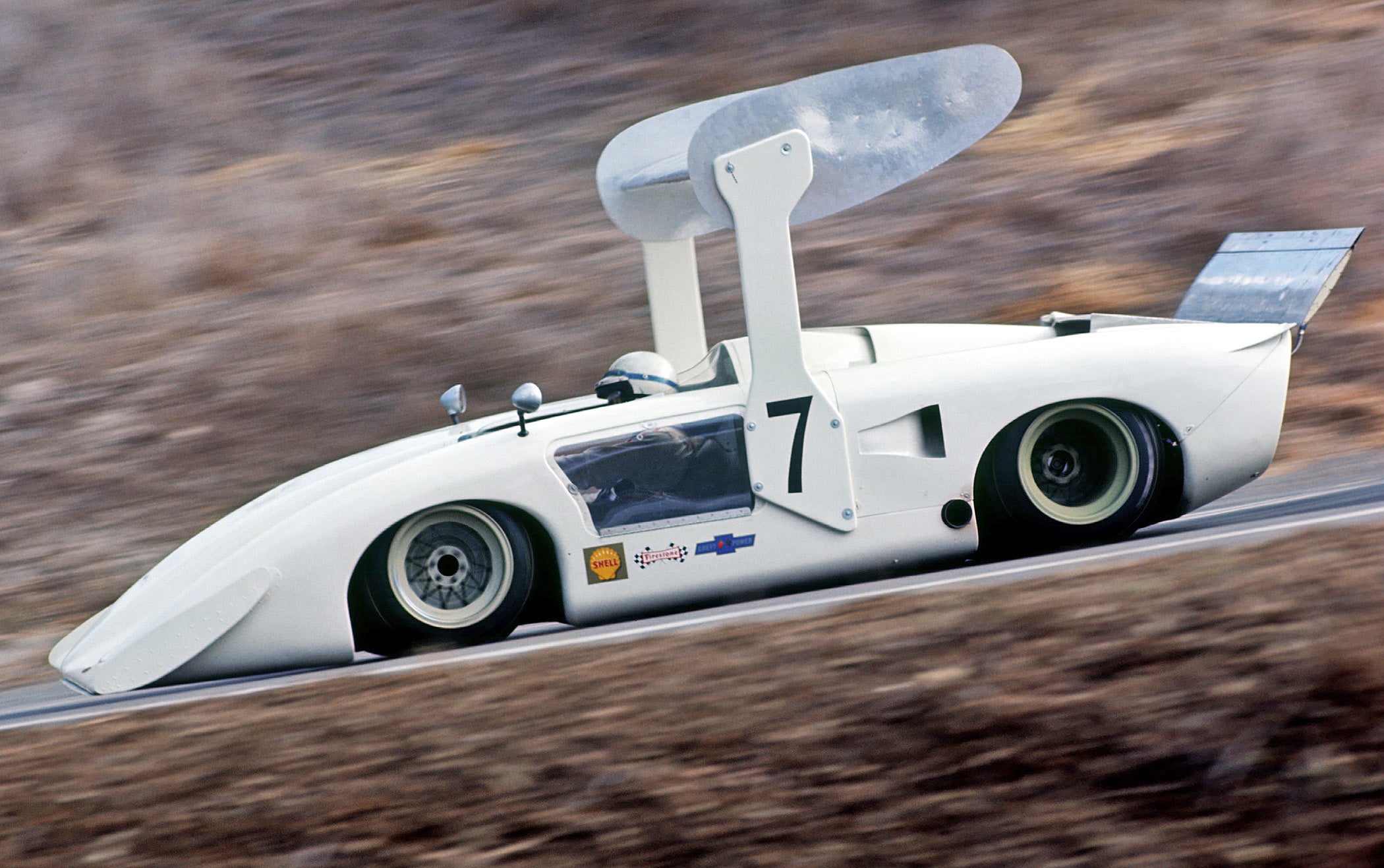

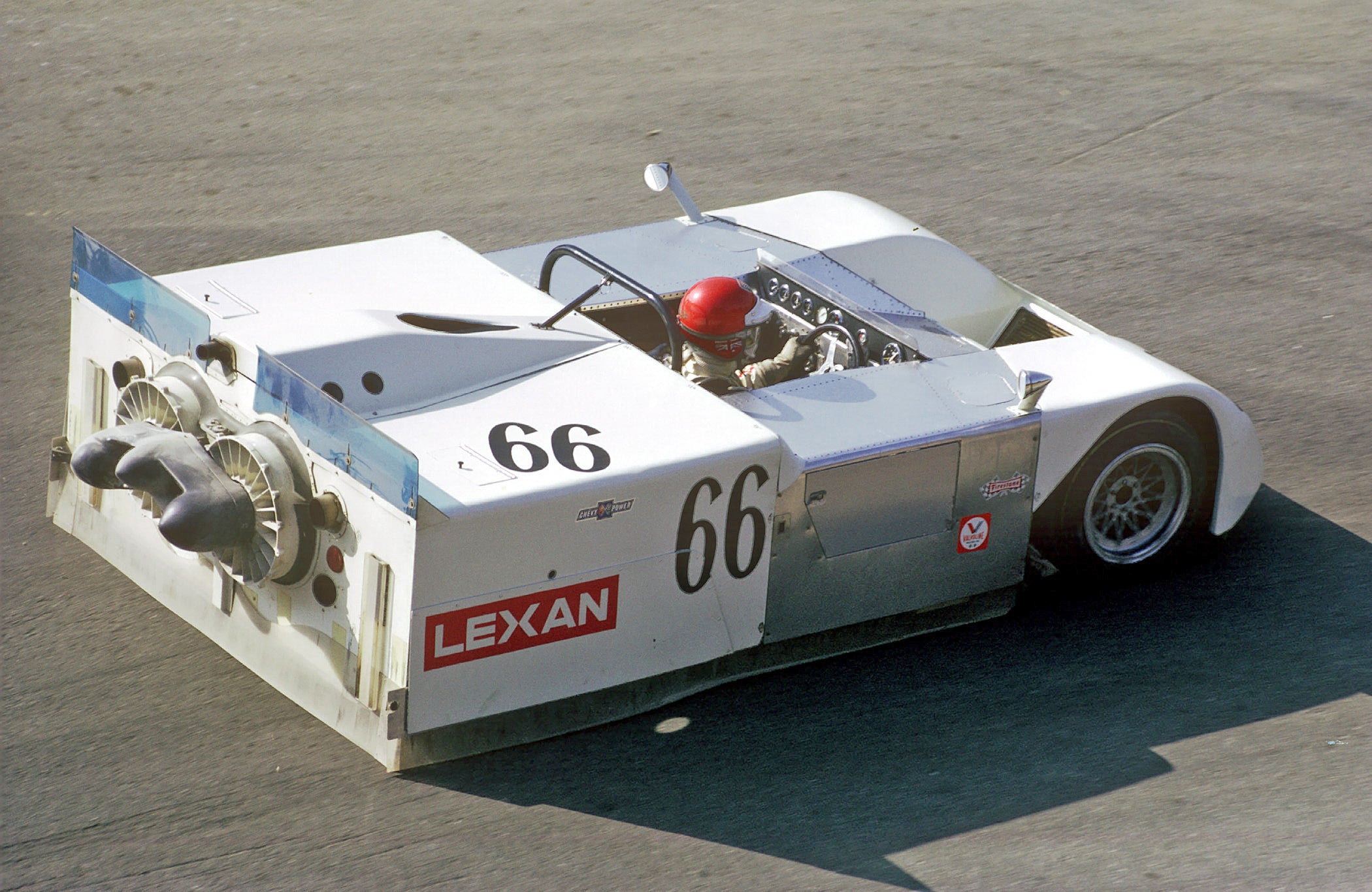

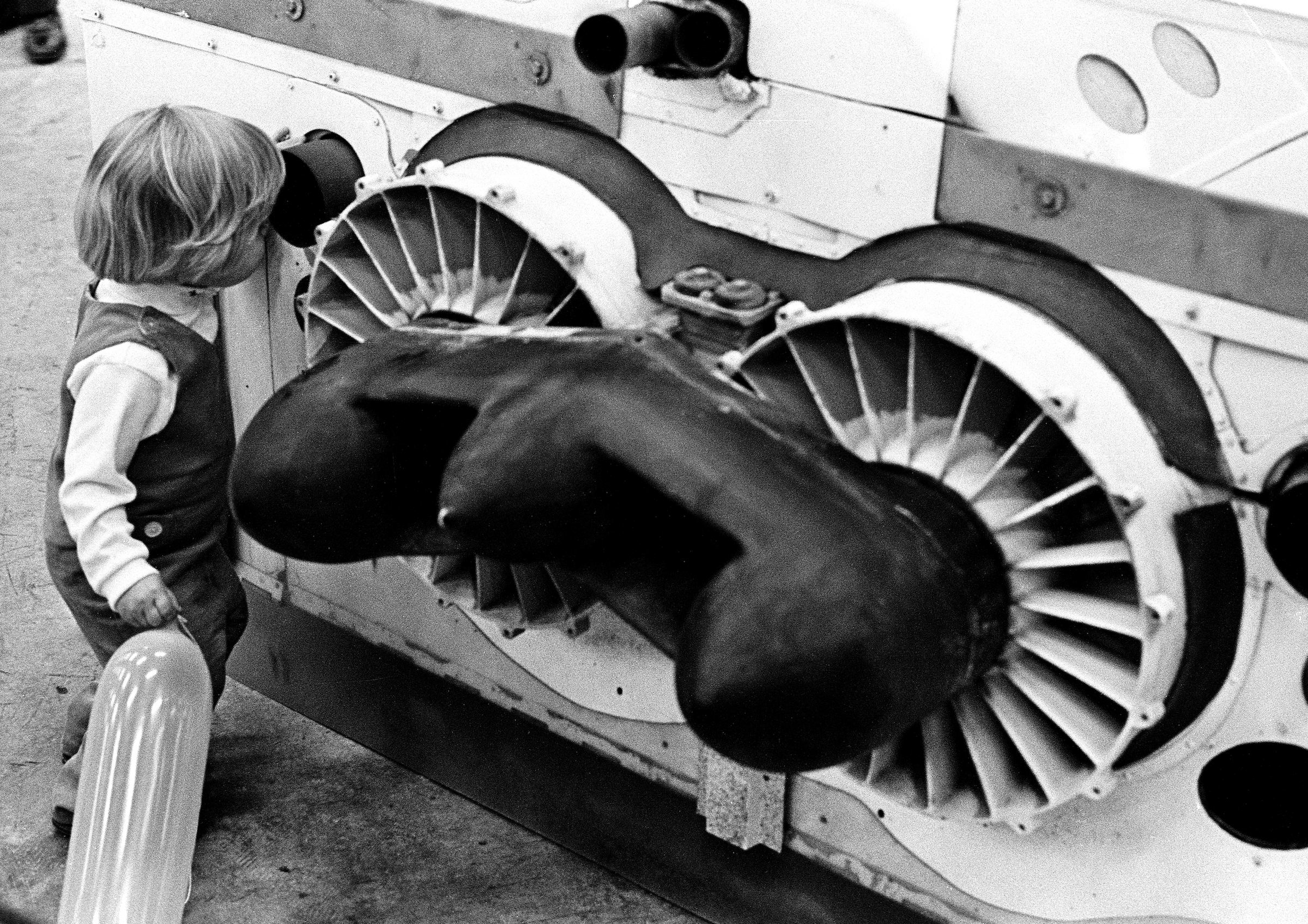

• The massive influence of his introduction of net downforce to racing, which is now incorporated into the design of every major type of four-wheel competition vehicle.

• How Hall shocked the world with innovative designs that won in every series in which they competed, including Can-Am, Trans-Am, the World Sportscar Championship, Formula 5000, United States Road Racing Championship, Canadian Sports Car Championship and the Indianapolis 500.

• How Jim and John Barnard created the Chaparral 2K “Yellow Submarine” that won the Indianapolis 500 and national championship, setting the template for the modern Indycar.

• The massive resistance Jim faced from teams and sanctioning bodies intent on outlawing his legal but game-changing innovations.

• The connection to Chevrolet and the crucial role Chaparral Cars played in the defense of GM during the Corvair trials of the mid-1960s.

• How Hall became a national celebrity, with Newsweek and Sports Illustrated covers, Coca-Cola commercials, and millions of “Jim Hall Authorized” slot cars and model kits.

• Text based on the author’s extensive interviews with over 100 racing standouts, including Jim and Sandy Hall, Roger Penske, Jackie Stewart, Dan Gurney, Sam Posey, Brian Redman, Phil Hill, Al and Bobby Unser, Bernie Ecclestone, Johnny Rutherford, Gordon Murray, Adrian Newey, Gil de Ferran, Mario Andretti, Bob Lutz and Tony Southgate.

• Big, beautiful and packed with facts and anecdotes, the book is lavishly illustrated with period photographs by many of the world’s best motorsports photographers, including Pete Biro, Bernard Cahier, Hal Crocker, Dave Friedman, Pete Lyons, Dan Boyd, Lionel Birnbom and Pulitzer Prize winner Bob Jackson.

Publication: 9 July 2024

Format: 240x210mm

Hardback

Page extent: 484

Illustration: 486 photos

We deliver to addresses throughout the world.

UK Mainland delivery costs (under 2kg) by Royal Mail £5.00.

Books will normally be shipped within two working days of order. Estimated delivery times post shipment. UK: Up to 5 working days. Europe, Northern Ireland and Highlands and Islands: Up to 8 days. USA: Up to 12 days

IMPORTANT NOTICE FOR EU CUSTOMERS: Delivered Duty Unpaid (DDU) means that customers are responsible for paying the destination country's customs charges, duties. Regrettably parcels will sometimes be held by customs until any outstanding payments are made. Any payments not received may result in courier returning or in some cases destroying your books.

Unwanted products can be returned with the original packaging within 14 days of delivery. Returns will be at your own cost.

If you receive a faulty or damaged item please contact orders@evropublishing.com for return and replacement information.